GST : 33AQOPS0137N1ZG

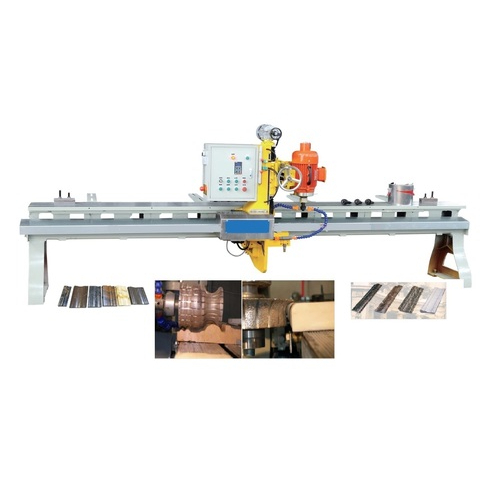

Granite edge moulding machine CI-99

Product Details:

- Product Type Other

- Technology Other

- Power Source Hydraulic

- Power 5.5 kw

- Surface Treatment Other

- Dimension (L*W*H) 4200*1600*1500 Millimeter (mm)

- Weight (kg) 1.5 Tonne

- Click to View more

Granite edge moulding machine CI-99 Price And Quantity

- 750000 INR/Piece

- 1 Piece

Granite edge moulding machine CI-99 Product Specifications

- Other

- According to stone density

- 4200*1600*1500 Millimeter (mm)

- Hydraulic

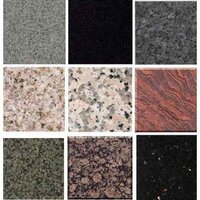

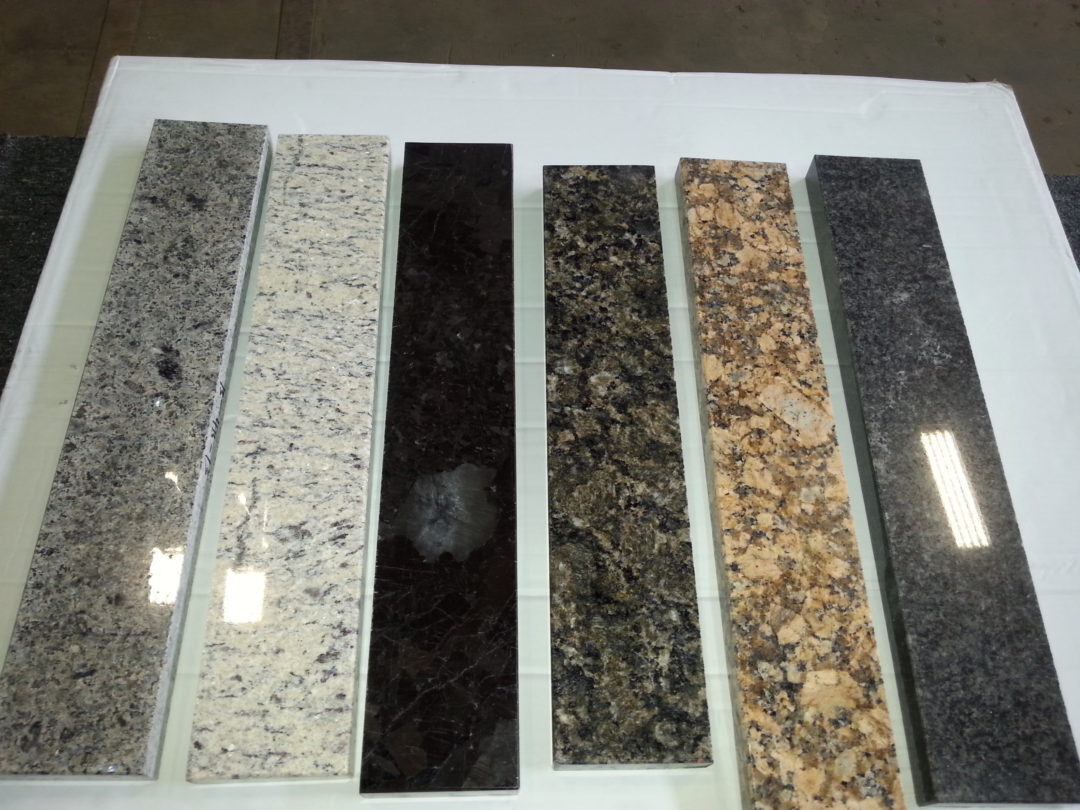

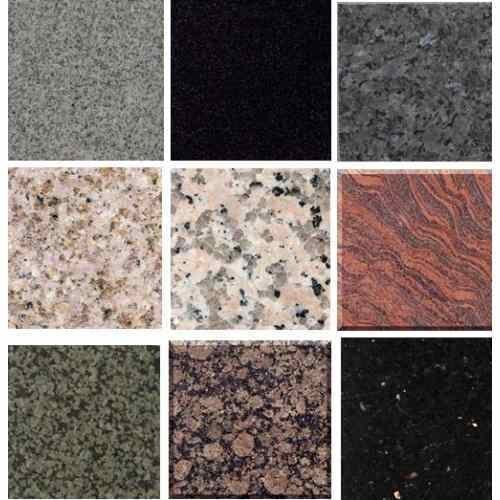

- Granite /marble

- 5.5 kw

- 1 year

- 1.5 Tonne

- Other

- Other

Granite edge moulding machine CI-99 Trade Information

- Coimbatore

- 1

- 2 Months

- Plastic bubble cover packing

Product Description

The electric machinery adopts double speed regulation withquick moulding and polishing Its lightness is better than ordinary machine The transmission part utilizes gear connectionThe mechanical vibrating force As a result it prolongs two to three years longer of the overall frameservice At present it is the highest edge arising accurancy machinery in themarket

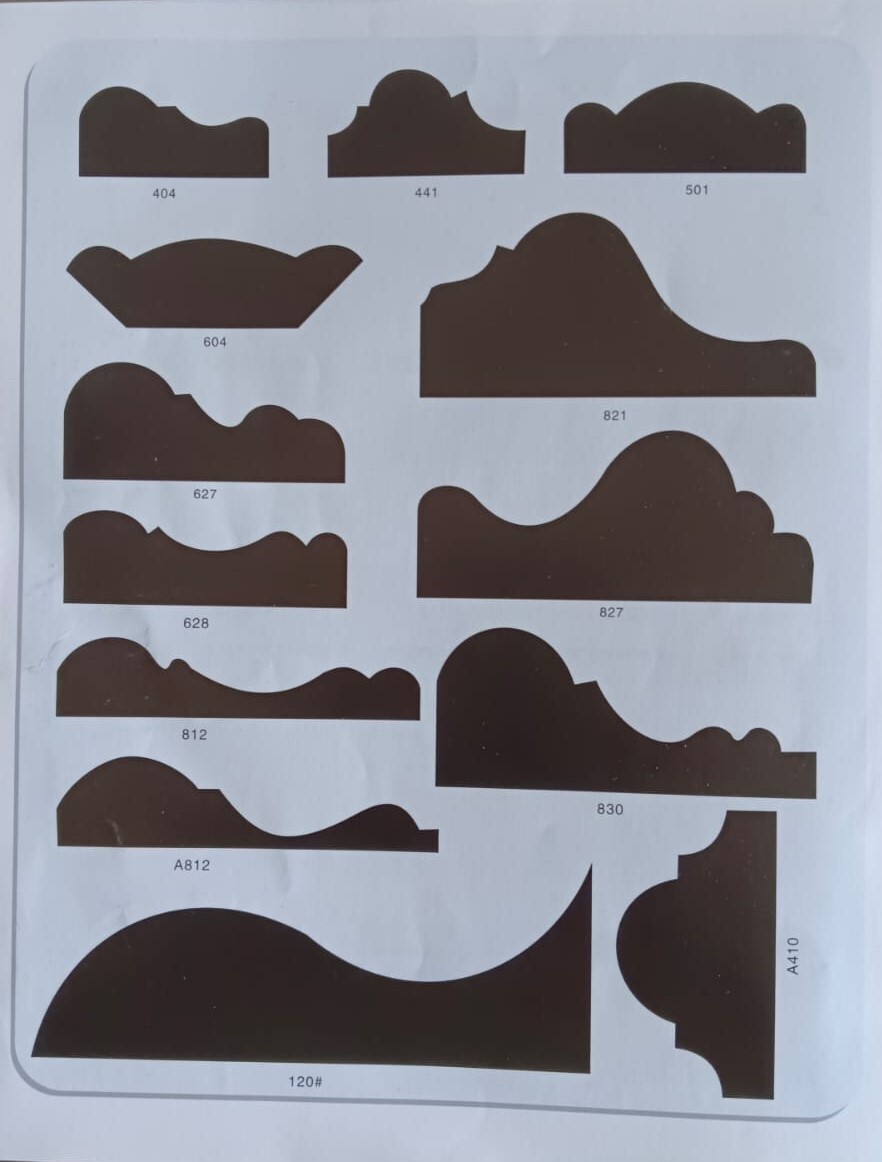

This machine uses double guide rails and twin paralleledwheels with enclosed oil immersion type and long service The head can be drawnout to grind curves The board under the washbin in internally circular withattractive and exquisite appearance It will enhance six to eight timesefficiency compared with the manual grinding Notable large feebing volume fine stability It integrates the straight line curve line lineation andinternal circular into a whole Nowadays it is the most advanced heterogenoustype of multi functional edge grinder

Advanced Hydraulic Power

The CI-99 utilises a powerful 5.5 kW hydraulic system, providing consistent and reliable performance for granite and marble edge moulding. This mechanism enhances both efficiency and precision, resulting in smooth finishes for various stone types. Its sturdy construction is built to withstand intensive, long-term operation in industrial settings.

Flexible Production Capacity

This machines output is determined by the density of the processed stone, allowing operators to adapt to different materials with ease. Whether working with granite or marble, the CI-99 maintains its effectiveness and throughput, making it an all-in-one solution for diverse edge moulding requirements encountered by suppliers and traders.

FAQs of Granite edge moulding machine CI-99:

Q: How does the Granite Edge Moulding Machine CI-99 operate?

A: The CI-99 operates using hydraulic power, which drives its components to accurately shape and polish the edges of granite and marble. The process is controlled via its integrated system to achieve consistent, high-quality results.Q: What are the main applications for the CI-99 moulding machine?

A: The machine is primarily used for edging granite and marble slabs, making it essential for stone fabrication plants, workshops, and manufacturers that require precise edge finishes for countertops, tiles, and architectural stone pieces.Q: When is the best time to perform routine maintenance on the CI-99?

A: Routine maintenance should be scheduled based on machine usage, following the manufacturers guidelinesideally every few months or after a significant production cycleto ensure long-term reliability and optimal performance.Q: Where is the CI-99 granite edge moulding machine available in India?

A: The CI-99 is distributed, manufactured, supplied, and traded by various companies across India. Interested buyers can contact certified distributors or manufacturers for purchases, installation, and after-sales service.Q: What is the process for moulding granite edges using this machine?

A: The stone slab is positioned on the work table and secured, then the hydraulic-powered moulding head is activated. The machine shapes and refines the edge to the desired profile, accommodating different stone densities for uniform results.Q: How can users benefit from the CI-99s adjustable production capacity?

A: The machines capacity adjusts according to the density of the stone, allowing operators to work efficiently with both granite and marble. This adaptability ensures consistent production quality regardless of material differences.Q: Is the CI-99 covered by any warranty?

A: Yes, the machine comes with a 1-year warranty covering manufacturing defects and performance issues, providing users peace of mind and support during the initial operational period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+