GST : 33AQOPS0137N1ZG

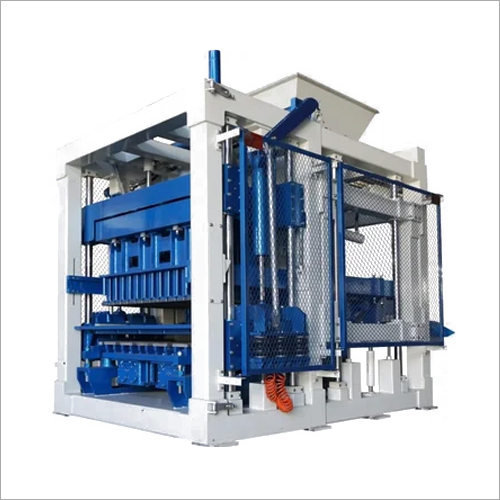

Colour Paver Block Machine manufacture in coimbatore

Product Details:

- Product Type pavar block

- General Use construction

- Method Hydraulic Pressure

- Processing Brick Production Line

- Automatic Yes

- Power 30+kw

- Voltage 440 Volt (v)

- Click to View more

Colour Paver Block Machine manufacture in coimbatore Price And Quantity

- 4800000.00 INR/Piece

- 1 Piece

Colour Paver Block Machine manufacture in coimbatore Product Specifications

- 30+kw

- 25

- Brick Production Line

- 1

- 24

- pavar block

- Cement

- Hydraulic Pressure

- 440 Volt (v)

- construction

- grey,ivary

- Solid Brick Making Machine

- Yes

Colour Paver Block Machine manufacture in coimbatore Trade Information

- 1 Piece Per Day

- 5 Days

- Asia

- All India

Product Description

Main Technical Performance and Parameter

Target User: requires high production output of concrete blocks, in different types, sizes, shapes and colours. Applied Products: Concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edges, curb stones, grass blocks, slope blocks, interlocks etc

Applied Fields: Widely used in buildings, road paving, squares, gardens, landscaping, city constructions, etc

Raw Materials: Crushed stone, sand, cement, lime, flyash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

Main Features: Uses Delta PLC control system and Delta Touch Screen.

A. Visualization screen with easy operation;

B. Is able to set up, update and amend the production perimeters, to maximize the production output;

C. Dynamic display ofthe system status, automatic trouble shooting and warning notice;

D. Has automatic-locking function, avoiding mechanical accidents caused by operational mistakes;

E. Is able to troubleshoot the machineny via teleservice. Uses high dynamic proportional and directional valves, which automatically adjust the pressure as per specific working requirements to buffer the hydraulic cylinder when working; uses integrated high pressure and soft oil pipes, with easy installation; Uses 3600 multi shaft rotating and compulsory feeding, which greatly improves the density and ofthe blocks, and reduces the feeding time as well; Integrated structure of vibrating and moulding platforms, which reduces the weight of the machine, improves the vibrating efficiency; Four rods guiding system and high-precision long guide bushing are used to assure the precise movement between the tamper head and the mould; Heavy duty machine frame which uses high density steel and advanced welding technology is vibration proof.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+