Hi density paver block making machine C I-615-A

Product Details:

- Product Type Automatic

- General Use construction

- Method Hydraulic Pressure

- Processing Brick Cutting Machine

- Automatic Yes

- Power 30 kw

- Voltage 440 Volt (v)

- Click to View more

Hi density paver block making machine C I-615-A Price And Quantity

- 1 Piece

- 9500000 INR/Piece

- 9500000.00 - 11000000.00 INR/Piece

Hi density paver block making machine C I-615-A Product Specifications

- Yes

- 440 Volt (v)

- 30 kw

- 24

- Automatic

- Brick Cutting Machine

- 1 year

- Hydraulic Pressure

- Cement

- 24 Metric Ton

- 6670*2245*2780 Millimeter (mm)

- construction

Hi density paver block making machine C I-615-A Trade Information

- Coimbatore

- 2 Months

- plastic bubble cover packing

- All India

Product Description

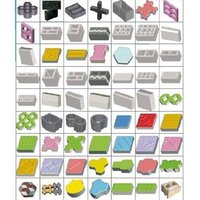

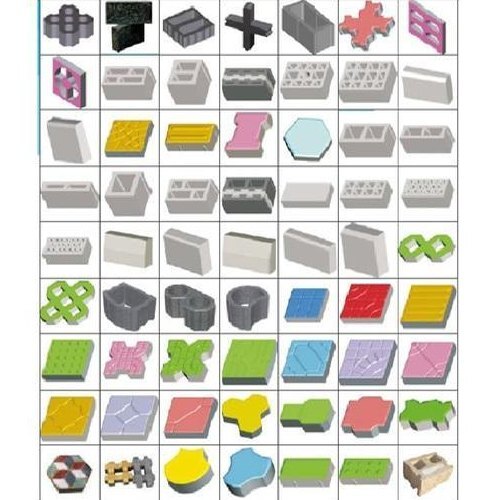

1.This machine is Hi density mutli block making machine

2.Super strong structure made of extensive imported original parts ensuring more stability and reliability for the main machine body

3.The whole process uses a PLC aptitude control and dialogue system of human machine interface easy to analyse the chance signal ensure the best operation effect

4.High efficient and super strong vibration system computer control flow pressure of the hydraulic system realize vertically synchronous vibration frequency conversion and braking with synthetic output compounded with double vibration thus greatly increase product compactness and mould box service life

5.The cloth system adopts semi closed screen reticular rotational feeding unit to feed materials forcedly with evenness and even speed ensuring product intensity

6.Fitted with special hydraulic loading unit readily realize mass and automatic production saving a great deal of human power maintenance field and circulating fund investment